Mean effective pressure formula, how to measure the pressure, how to find mean of grouped data, how to find the mean, how to find the area of a circle, how to draw, how to recall an email in outlook, how to delete a page in word,

As an expert in the field of mechanical engineering, one of the most essential terms you ought to know is mean effective pressure (MEP). MEP refers to the average pressure equivalent, which moves the piston of a reciprocating engine from top dead center (TDC) to bottom dead center (BDC). MEP is a crucial parameter to measure the performance and power output of an engine.

Understanding MEP

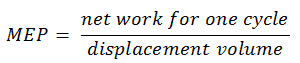

MEP is a calculated value used to characterize the performance of an internal combustion engine. It is determined by measuring the force generated by the combustion gases in the engine's combustion chamber and then dividing that value by the engine's displacement. The output of this calculation is an indicator of the power output of the engine.

The pressure generated in the combustion chamber during the power stroke is higher than the atmospheric pressure. MEP is calculated by determining the average pressure generated during the engine's operating cycle. This includes the motion from TDC to BDC and back to TDC.

MEP is measured in Pascals (Pa) or pounds per square inch (psi). Higher MEP means the engine is more efficient and powerful. A greater MEP can be obtained by increasing the compression ratio, increasing the fuel injection pressure, or using a turbocharger in diesel engines.

The Importance of MEP

MEP plays a crucial role in the optimization of internal combustion engines. It is an essential parameter for analyzing the performance of engines, and it helps engineers to optimize engine designs and improve efficiency. Through the use of MEP, engineers can determine the optimal pressure ratio, compression ratio, and other key factors that can improve engine performance. MEP can also be used to identify potential problems with an engine's operation, such as excessive cylinder leakage, poor valve timing, or other issues that may degrade engine performance.

Moreover, MEP is essential in the design and development of new engines. By measuring MEP, engineers can test and refine their designs and determine which changes can improve overall engine efficiency. This process can help manufacturers to reduce emissions, improve fuel economy, and increase the overall performance of their engines.

Types of MEP

There are two main types of MEP: brake mean effective pressure (BMEP) and indicated mean effective pressure (IMEP).

Brake Mean Effective Pressure (BMEP)

BMEP refers to the average pressure exerted on the flywheel of an engine. It is calculated by measuring the power output of the engine using a dynamometer and dividing it by the engine's displacement. This value is given in units of psi or bar and is an important parameter for evaluating the overall performance of the engine.

Indicated Mean Effective Pressure (IMEP)

IMEP refers to the average pressure generated in the combustion chamber during the power stroke. It is calculated using an engine's indicator diagram, which measures the pressure inside the combustion chamber at different points during the engine cycle. IMEP gives an accurate measurement of an engine's performance as it accounts for all of the energy produced during the combustion process, including the losses resulting from the friction and internal leakage. IMEP is expressed in units of psi or bar.

MEP Applications

MEP is a crucial parameter in designing, evaluating, and optimizing internal combustion engines. It plays an essential role in developing new engine technologies and improving the performance of existing engines. MEP is widely used in various applications such as:

Engine Optimization

Engine manufacturers use MEP to optimize the design and performance of internal combustion engines. Engineers can use the MEP values to refine the critical components of an engine, such as the combustion chamber and fuel injection system, to improve engine performance.

Automotive Industry

In the automotive industry, MEP is used to measure the performance of an engine and to test the engine's overall efficiency under different operating conditions. It is also used in emission and fuel economy testing to ensure compliance with government regulations.

Industrial Applications

MEP is important in industrial applications such as power generation and marine propulsion. Accurate measurement of MEP can be used to troubleshoot engines and identify potential problems before they cause significant damage. It also provides a reliable indicator of engine performance and can be used to optimize engine designs for specific applications such as power generation or marine propulsion.

Research Purposes

Researchers and academic institutions use MEP to understand the fundamental principles of combustion and to explore new combustion technologies. MEP is fundamental in research to understand the effects of combustion parameters such as fuel injection timing and cylinder pressures on engine performance and emissions.

The Bottom Line

MEP is a crucial parameter in the field of mechanical engineering. It plays a critical role in the design, optimization, and testing of internal combustion engines. MEP is essential in developing new technologies that are more environmentally friendly and cost-effective. It also provides a reliable measure of engine performance, which can be used to optimize engine designs for various applications. The importance of MEP will continue to grow as the world seeks more efficient and sustainable energy solutions.

References:

1. What is Mean Effective Pressure MEP Otto cycle Definition. Retrieved from https://thermal-engineering.org/mean-effective-pressure-definition/

2. Mean effective pressure of an engine. Retrieved from https://www.youtube.com/watch?v=ZIv8WnAHB7w